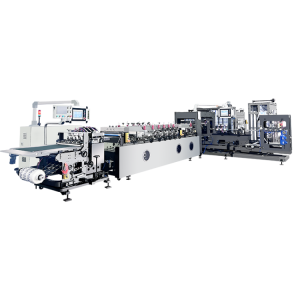

NCA300sja Tas kanthi otomatis NCA300sja lan Mesin Spout-Welding

Dianggo

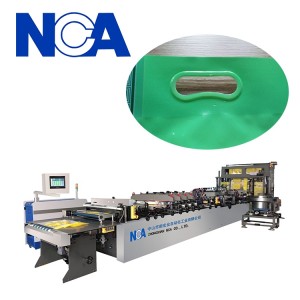

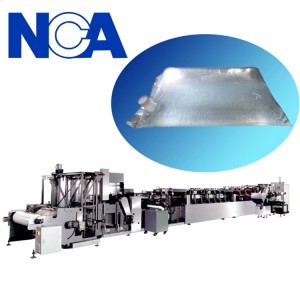

1. Mesin digunakake kanggo nggawe tas saling telung sisih utawa tas sing ngadeg kanthi spout saka film laminasi plastik.

2. Mesin kasebut wiwit ora kesusu, giliran bubuk bubuk magnetik, nglereni, nyepetake, (bentuk puncher), nglacak celon, (jancok adhem), nglereni celon, ngethok puncher), produk mbukak meja.

Kauntungan

1.welding muncung, mesin nggawe tas

Tas independen, panyimpenan (ngisi tanpa mandheg)

3. Mbukak piso, gulung kaping pindho

Proses kerja

Mesin kasebut wiwit ora suwek, giliran bubuk bubuk magnetik, nglereni, nyepetake, sudut puncher, nglacak seluler, nglacak celon hot sealing, nglereni celon celon, nglereni (Motong puncher), produk mbukak meja.

Parameter teknik Mesin

| 1 | Bahan Film | Film laminasi plastik |

| 2 | Kapasitas: | Bag Feed Tunggal: Max35-40PCS / Feed Bag Mindo: Max 70-80PCS / Min |

| 3 | Ketebalan materi | 0,06 ~ 0.15mm |

| 4 | Jinis spout | Macem-macem jinis plastik cilik. |

| 5 | (Kacepetan kanggo kanthong, kacepetan khusus miturut ukuran lan materi (bahan) | |

| 6 | Ukuran Pouch: (l × w) | Bag Feed Tunggal: Bag Bag Bag 20000 × 200mmdublong: Max150 × 100mm |

| 7 | Kekuwatan total | Udakara 25kw |

| 8 | Tegangan daya | AC380V, 50Hz, 3p |

| 9 | Tekanan Udara: | 0.5-0.7MPA |

| 10 | Banyu pendinginan: | 10l / min |

| 11 | Dhuwur meja makarya: | 950mm |

| Ngalahake Operasi Dhuwur 850mm | ||

| 12 | Ukuran Mesin (Max): | L × W × H: 8200mm × 3500mm × 2000mm |

| 13 | Bobot Mesin: | udakara 5000kg |

| 14 | Werna Mesin: | Grey (Wallboard) / stainless steel (papan penjaga) |